Design custom blades for your generator and calculate power output at each wind speed.

Free sample chord sections can be generated for 0.70 m to 0.80 m blades (550 Watts - 710 Watts).

Free plans for 500 W blades with each purchase.

Enable Ads for www.warlock.com.au

SPONSORED ADVERTISEMENT

10 kW (13 m/s) 5 m Diameter Carbon Fibre Wind Turbine Blades

Abstract

A 10 kW wind turbine blade set has been built for use with the 10 kW, 15 phase Axial flux pancake generator. When attached to the turbine it is estimated to produce approx 4-5 kW of electrical power at 50% efficiency with 8-10 kW of mechanical power driving the generator. The total cost of the turbine blades was AU$405 and the blades were constructed with typical home-workshop tools.

Keywords: Wind power, Wind turbine blade construction, 10 kW wind turbine, Carbon fibre wind turbine blades

LIST OF FIGURES

1. Constructing the interior of the wind turbine blades

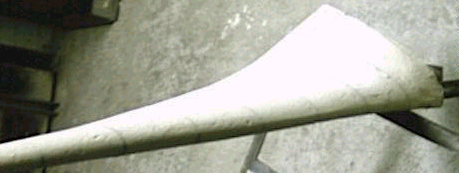

Figure 1. Steel blade core

Figure 2. Skeleton airfoil blade one

Figure 3. Skeleton airfoil blade two

SPONSORED ADVERTISEMENT

Figure 4. Skeleton filled with polyurethane foam

The skeleton was filled with expanding polyurethane foam (1kg Suprasec 5005, 1kg Daltolac GP33) and sanded into shape.

2. Constructing the exterior of the wind turbine blades

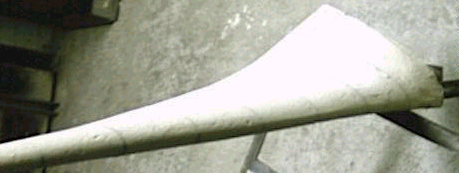

Figure 6.

Blade after being covered in chop strand matt fibreglass

The blade was coated in a layer of vinyl ester resin and once the resin had cured, 220 g chop strand matt fibre glass was used to fibreglass the blades, this was does several times with sanding to ensure a smooth finish.

Figure 7.

Blade after being covered in bi-axial glass cloth fibreglass

400g bi-axial glass cloth was wrapped around the blade and fibre glassed in place. It was lightly sanded before applying another layer of chop strand matt.

Figure 8.

Blade after being covered in uni-directional carbon fibre

Chop strand matt was sanded into shape before applying the final layer of 197g uni-directional carbon fibre. The carbon fibre is lightly sanded to form a smooth flat blade

Figure 10.

Completed 5 m wind turbine blades

Running at a TSR of 12.5 the generator should output 4kW electrical power, requiring 8kW mechanical power

Rotational Torque = 121.45 N.m

Rotational Speed = 620.7 RPM

Mechanical Power = 7894.3 Watts

Blade Efficiency = 0.3

TSR = 12.5

A TSR of 12.5 is a better match to the generator

Running at a TSR of 9, the generator should output 2kW electrical power, requiring 4kW mechanical power

Rotational Torque = 224.91 N.m

Rotational Speed = 446.9 RPM

Mechanical Power = 10,525.7 Watts

TSR = 9

Blade Efficiency = 0.4

Output of system at maximum generator output (generator efficiency of 50%)

3. Calculated output of the wind turbine system

At a total cost of $1,278 including the generator, a wind turbine capable of producing 4-5kW

electrical power makes a very cheap alternative for power production especially in remote areas.

System cost (AUD)

Steel $25

Polyurethane $40

Matt, cloth, resin and initiator (MEKP) $220

Carbon fibre (increased strength, not essential) $120

Total cost $405

Equipment used

Arc welder

Grinder

Drill

Wood saw

Sand paper

Fibreglass rollers

Paint brushes

Conclusion

4. Total cost of the wind turbine blades

Frequently asked questions about plan orders, blade design, electrical work and generator matching can be found on our Q&A pages.

Abstract

A TSR of 12.5 is a better match to the generator

Output of system at maximum generator output (generator efficiency of 50%)

3. Calculated output of the wind turbine system

At a total cost of $1,278 including the generator, a wind turbine capable of producing 4-5kW electrical power makes a very cheap alternative for power production especially in remote areas.

System cost (AUD)

Steel $25

Polyurethane $40

Matt, cloth, resin and initiator (MEKP) $220

Carbon fibre (increased strength, not essential) $120

Total cost $405

Equipment used

Arc welder

Grinder

Drill

Wood saw

Sand paper

Fibreglass rollers

Paint brushes

Conclusion

4. Total cost of the wind turbine blades

2. Constructing the exterior of the wind turbine blades

Figure 5. Polyurethane foam blade after sanding

Figure 6. Blade after being covered in chop strand matt fibreglass

Figure 7. Blade after being covered in bi-axial glass cloth fibreglass

Figure 8. Blade after being covered in uni-directional carbon fibre

Figure 10. Completed 5 m wind turbine blades

Figure 9. Blade after sanding the carbon fibre

Rotational Torque = 224.91 N.m

Rotational Speed = 446.9 RPM

Mechanical Power = 10,525.7 Watts

Blade Efficiency = 0.4

TSR = 9

Running at a TSR of 9, the generator should output 2 kW of electrical power, requiring

4 kW mechanical power

4 kW mechanical power

TSR = 12.5

Blade Efficiency = 0.3

Mechanical Power = 7894.3 Watts

Rotational Speed = 620.7 RPM

Rotational Torque = 121.45 N.m

Running at a TSR of 12.5 the generator should output 4 kW electrical power, requiring 8 kW mechanical power

Chop strand matt was sanded into shape before applying the final layer of 197g uni-directional carbon fibre.

The carbon fibre is lightly sanded to form a smooth flat blade.

The carbon fibre is lightly sanded to form a smooth flat blade.

The blade was coated in a layer of vinyl ester resin and once the resin had cured, 220 g chop strand matt fibre glass was used to fibreglass the blades. Several layers were used with sanding to ensure a smooth finish.

400g bi-axial glass cloth was wrapped around the blade and fibre glassed in place. It was lightly sanded before applying another layer of chop strand matt.

Related Articles

| Figure | Page | |

| 1 | Steel blade core | 1 |

| 2 | Skeleton airfoil blade one | 1 |

| 3 | Skeleton airfoil blade two | 2 |

| 4 | Skeleton filled with polyurethane foam | 2 |

| 5 | Polyurethane foam blade after sanding | 2 |

| 6 | Blade after being covered in chop strand matt fibreglass | 3 |

| 7 | Blade after being covered in bi-axial glass cloth fibreglass | 3 |

| 8 | Blade after being covered in uni directional carbon fibre | 3 |

| 9 | Blade after sanding the carbon fibre | 4 |

| 10 | Completed 5 m wind turbine blades | 4 |

The airfoil shapes were printed using a computer. The printouts were glued on 1 mm steel sheet and cut out.

The steel airfoil cut-outs were welded on steel tube, with the angle set using a protractor against a plumb line.