10 kW, 15 phase Axial Flux Pancake Generator

for 2-Blade Wind Turbine

for 2-Blade Wind Turbine

Abstract

A 10 kW permanent magnet electric generator has been built and tested for use with a high TSR, 5 m blade diameter wind turbine. The system was configured for 15 phase, 15 coils and 16 poles. Each coil is individually rectified to dc, reducing cogging and allowing better control over the output voltage. Total cost of the generator was AU$873 and was constructed with typical home-workshop tools.

Keywords: Wind power, Permanent Magnet Generator, 10 kw wind turbine

| Figure | Page | |

| 1 | Rear half of the generator rotor | 2 |

| 2 | Front half of generator rotor | 2 |

| 3 | Generator stator | 3 |

| 4 | Front half of generator rotor with magnets attached | 3 |

| 5 | Assembled generator | 4 |

| 6 | Testing the assembled generator | 5 |

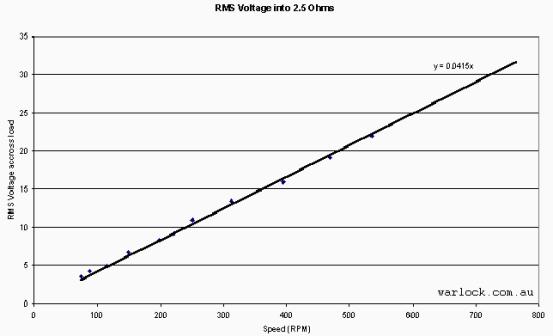

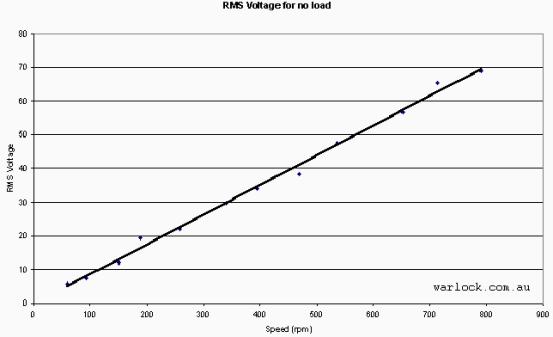

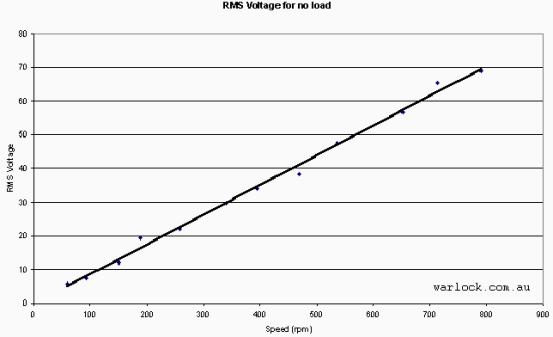

| 7 | Measured RMS Voltage under no load. 2.5 Ohm internal resistance | 6 |

| 8 | Measured voltage into matched load (2.5 Ohm) | 6 |

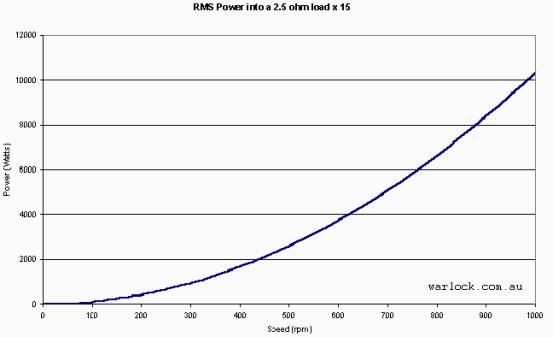

| 9 | Measured RMS power generated for all 15 coils into a matched load | 7 |

LIST OF FIGURES

2. Generator Assembly

1. Construction of the Permanent Magnet Generator

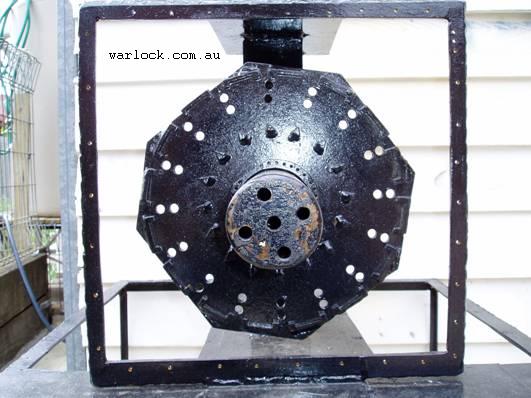

The rear plate (rotor) is mounted on a trailer axle bearing and holds the first set of 16 neodymium magnets.

Figure 2. Front half of generator rotor

The front plate holds the second set of 16 neodymium magnets. This plate is bolted to the rear half of the generator rotor, completing the magnetic circuit.

15 Independent coils have been fixed into the stator using 24 hour epoxy resin. The coils have a thickness of 12 mm, measuring 2.5 Ohms each and are wound using 0.6 mm diameter wire. This stator will be remade out of fibreglass and the holes in the centre of the coils will be reduced to increase the power output. Epoxy and aluminium should be avoided in the generator. Epoxy softens at temperatures as low as 60oC and aluminium has no fatigue limit, so any infinitesimally small stresses will eventually cause failure.

Figure 4. Front half of generator rotor with magnets attached

Figure 5. Assembled generator

The generator was assembled with the stator coils sandwiched between the two sets of magnets. A clearance of 2mm was given between coils and magnets. Care was taken in assembly as the magnetic force acting on the 32 magnets can be up to 640 kg!

The generator spins feely until current flows and this is due to no iron being in the stator. The absence of cogging significantly helps starting in very low wind.

The neodymium magnets used are grade N38 with dimensions; 2 inch x 1 inch x 0.5 inch, magnetised through the thickness.

16 magnets are fitted into the slots of both the front and rear plates. The magnets are arranged with alternating poles around the circumference of the plate. 32 holes have been drilled into both plates to help cooling of the coils.

Figure 8. Measured voltage into matched load (2.5 Ohm)

Figure 9. Measured RMS power generated for all 15 coils into a matched load

Frequently asked questions about plan orders, blade design, electrical work and generator matching can be found on our Q&A pages.

Figure 1. Rear half of the generator motor

Figure 3. Generator Stator

3. Total cost of the Permanent

Magnet Generator

Magnet Generator

System cost (AUD)

Magnets $500

2000m 0.6mm magnet wire $88

2 Trailer axles $60

Steel $50

Primer and enamel paint $70

Welding rods $20

Metal cutting discs $40

Connector strips $25

Bolts and nuts $20

Total cost $873

4. Testing the Permanent Magnet Generator

Figure 6. Testing the assembled generator

The generator was tested by attaching the drill to the generator. The speed of the drill and generator was controlled by an auto-transformer. Only one of the coils was put under load. The power produced by the coil was multiplied by 15 to get the total power of the generator.

SPONSORED ADVERTISEMENT

5. Measured results of the Permanent Magnet Generator

Figure 7. Measured RMS Voltage under no load. Internal resistance is 2.5 Ohms

RMS Power is calculated using the equation;

P = 15 x (V2 / R)

P = 15 x (V2 / R)

6. Equipment used

Arc welder

Angle grinder

Drill

Hacksaw

Oscilloscope

Auto-transformer

A generator capable of generating up to 10 kW has been built using cheap, readily obtainable parts for a total cost of $873. This compares favourably as an inexpensive alternative to the commercial generators.

SPONSORED ADVERTISEMENT

Free plans for 500 W

blades with each purchase

blades with each purchase

Free sample chord sections can be generated for 0.70 m to 0.80 m blades (550 Watts - 710 Watts).

Voltage and frequency was measured on a oscilloscope. Generator speed, open circuit voltage and voltage under load (2.5 Ohms) were recorded. Speeds above 500 RPM generated considerable heat and requires cooling.

7. Conclusion

Related Articles

Welcome to Warlock Engineering's free Web-Applications *** Free Software, Tools & Apps. ***

Welcome to Warlock Engineering's free Web-Applications *** Free Software, Tools & Apps. ***